overview.

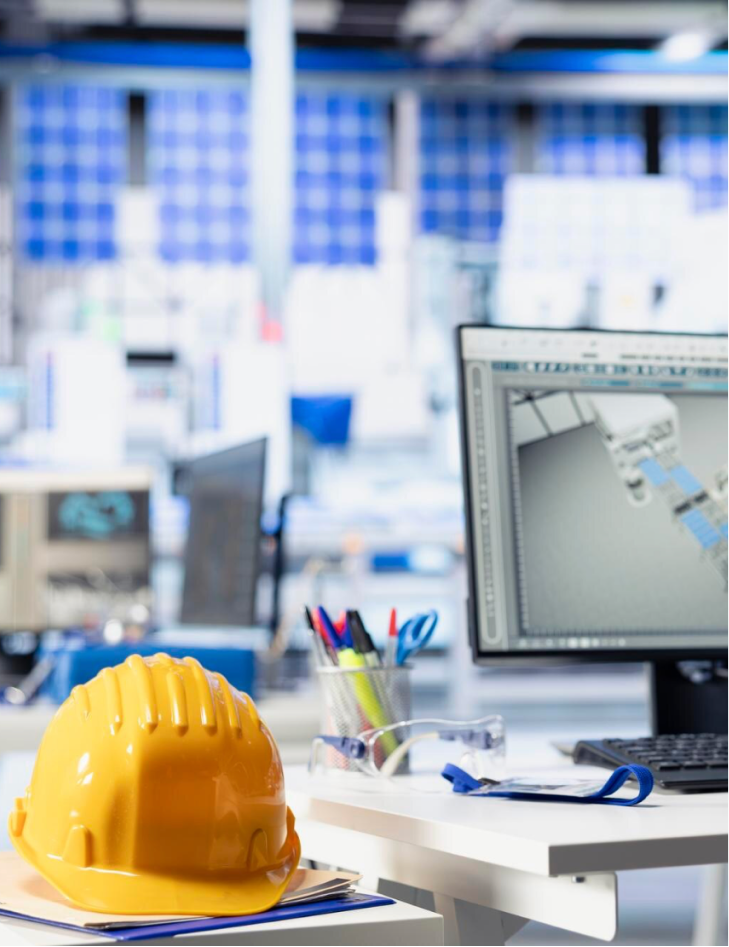

Essence of Precision Engineering & Quality Assurance

At T.T.E. Engineering, precision engineering and quality assurance are advanced technological practices that integrate digital innovation, real-time monitoring and data-driven validation to deliver exceptional HVAC, cleanroom and utility systems. Our proprietary approach uses Building Information Modeling (BIM), 3D coordination software and advanced simulation tools to ensure design accuracy and prevent costly onsite issues.

We leverage automated quality control platforms and sensor-based inspections to provide continuous verification throughout project execution. These systems are supported by digital workflows aligned with ISO 9001 and CIDB G7 standards, enabling comprehensive traceability and audit readiness. By embedding precision at every stage, from conceptual design to commissioning, T.T.E. Engineering guarantees reliability, compliance and operational excellence for complex industrial and critical environments.

Reduced Project Risks

Early digital validation minimizes onsite rework and unexpected delays.

Enhanced System Performance

Simulation-backed design leads to optimally functioning HVAC and cleanroom environments.

Transparent Quality Oversight

Real-time inspection data and digital reports ensure full traceability and accountability.

Faster Project Delivery

Coordinated workflows and automated QA reduce bottlenecks and expedite commissioning.

Sustainable Asset Management

Analytics-driven maintenance plans improve operational efficiency and lower lifecycle costs.

Adoption & integration.

T.T.E. Engineering's Application

Tracer fog testing is used to validate HVAC performance and cleanroom airflow patterns, ensuring systems meet stringent environmental and efficiency requirements.

SpiderPlus is used as a mobile inspection tool to capture on-site data related to installation quality and system parameters. Digital checklists and photo documentation help streamlining the verification process and improve efficiency.

Our QMS ensures consistent quality control and assurance through standardized procedures, inspections and documentation across all project stages.

Post-installation, we analyze operational data to confirm system performance and inform predictive maintenance, extending equipment lifespan and reducing downtime.

Sectors We Serve.

Industry Applications

Semiconductor Manufacturing

High-precision digital QA ensures contamination control and environmental compliance.

Pharmaceutical and Healthcare Facilities

Rigorous airflow and pressure monitoring supported by real-time quality assurance.

Industrial Process Plants

Integrated system simulations optimize utility usage and energy efficiency.

Commercial Complexes and Data Centers

Coordinated BIM and sensor-driven inspections enhance HVAC reliability and comfort.

Research and Development Laboratories

Verified environmental conditions and traceable quality controls maintain regulatory compliance.