Additional Resources

Explore supporting materials to learn more about our services.

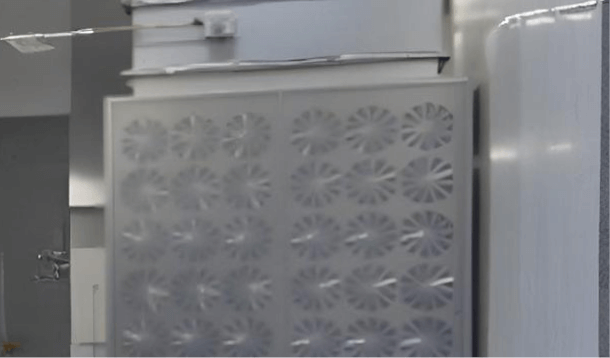

SWIT System

The SWIT System is a compact air delivery unit engineered for localized cooling in cleanrooms, process zones and equipment-intensive environments. T.T.E. Engineering integrates SWIT technology into facility designs that require efficient, targeted airflow without interfering with contamination control protocols.

By introducing air through swirling induction at low velocity, the SWIT System enables space-efficient cooling directly at heat-generating sources. Its compact form factor and displacement characteristics make it suitable for cleanroom-compatible applications where ceiling or wall-mounted cooling is not practical.

Benefits

Localized Heat Control

Provides direct cooling to equipment or zones with elevated heat loads, improving equipment reliability.

Cleanroom Compatibility

Operates with low turbulence, supporting ISO-classified environments and contamination control.

03.

Space Efficiency

Frees up overhead space in areas with limited installation clearance.

04.

Reduced Cooling Load

Enables targeted air supply, minimizing strain on central HVAC systems.

05.

Flexible Deployment

Suitable for both new construction and retrofit into existing HVAC infrastructure with minimal impact.

Technologies and Standards